Home / Products / Ceramic Capacitors / JYS

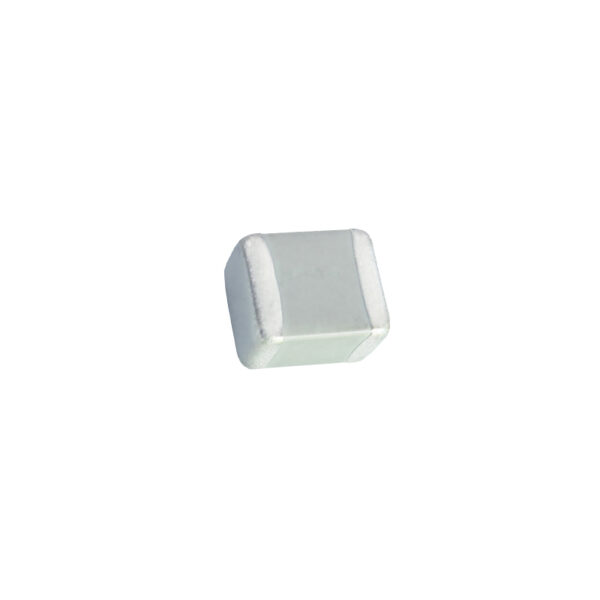

JYS – SMD Multilayer Ceramic Chip Capacitors

The JYS series from jb Capacitors features surface-mount multilayer ceramic chip capacitors designed for compact, high-frequency applications. With lower profile, low ESR, and high current capacity, they are ideal for wireless and portable devices. Built using a unique automated process, the JYS capacitors meet industry-standard sizes and offer multiple lead spacing options to support a wide range of PCB designs.

Description

Features

- related ICs needs of the wireless/portable systems.

- Lower profile, lower loss and higher Current in Compact Size is the design guide of our principles to design such inductors which made by unique automatic process.

- Industry standard size and various load spacing available.

Specifications

Specifications

| Dielectris & Values | NPO X7R X5R Y5V Z5U consult product pages of catalog for cap ranges and voltage rating |

|---|---|

| Terminations | Tin / Nickel |

| Voltage | 4, 6, 6.3, 10, 25, 50 VDC |

| Capacitance | 0.1pF ~ 100uF |

| Tolerance | ±0.1pF ~ +80-20% |

| Operating Temperature Range | NPO, X7R, X7T, X7S: -55 ~ +125℃;X6S: -55 ~ +105℃;X5R: -55 ~ +85℃;Y5V: -30 ~ +85℃ |

Drawing