Blog

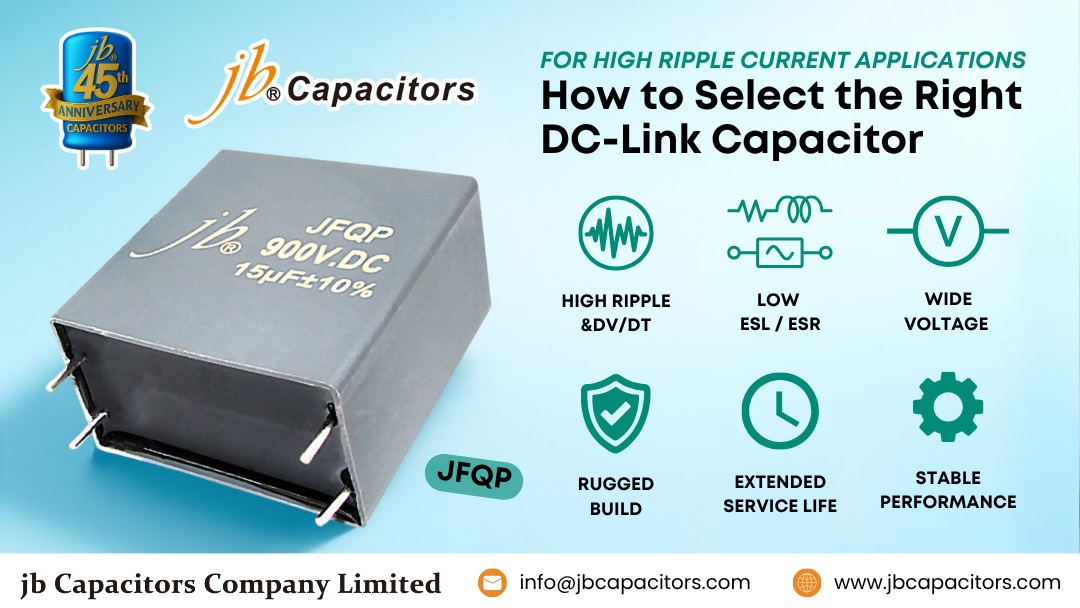

DC Link Film Capacitor – High Ripple Current JFQP Series

In modern power electronics, long lead times from major capacitor brands can derail production schedules. When a project depends on critical DC link components, waiting months for delivery may lead to delayed product launches, idle manufacturing lines, and dissatisfied customers.

Video Overview

The video below introduces the JFQP DC Link MKP Film Capacitors, showing their electrical capabilities, target applications, and how their short lead times can help avoid production bottlenecks.

Common Procurement Challenges

- Extended lead times from large brands → production delays

In many cases, major suppliers quote delivery windows of several months, making agile production nearly impossible. - High-cost procurement pressure

Urgent orders often mean paying premium prices, impacting project profitability.

Technical Advantages of JFQP Series

- High ripple current & dv/dt performance with low ESR/ESL

These factors directly reduce internal heating and improve efficiency, ensuring long service life under demanding switching conditions. - Wide electrical range: 500–1200 VDC, 0.68–110 µF

Supports diverse DC-Link, coupling, and filtering applications without design compromise.

Application Focus

The JFQP series is suited for:

- Industrial control systems requiring stable DC bus performance under variable load

- Solar inverters for renewable energy integration

- High-end power supplies for sensitive equipment

Why Lead Time Matters in DC Link Capacitors

For engineers and buyers sourcing dc link film capacitor high ripple current or low esr film capacitor designs, having a partner that can deliver within weeks rather than months reduces supply chain risks and gives flexibility for last-minute design changes. As an industrial power capacitor supplier, jb Capacitors ensures that the mkp dc link capacitor datasheet and full specs are available for precise design evaluation.